High performance trays

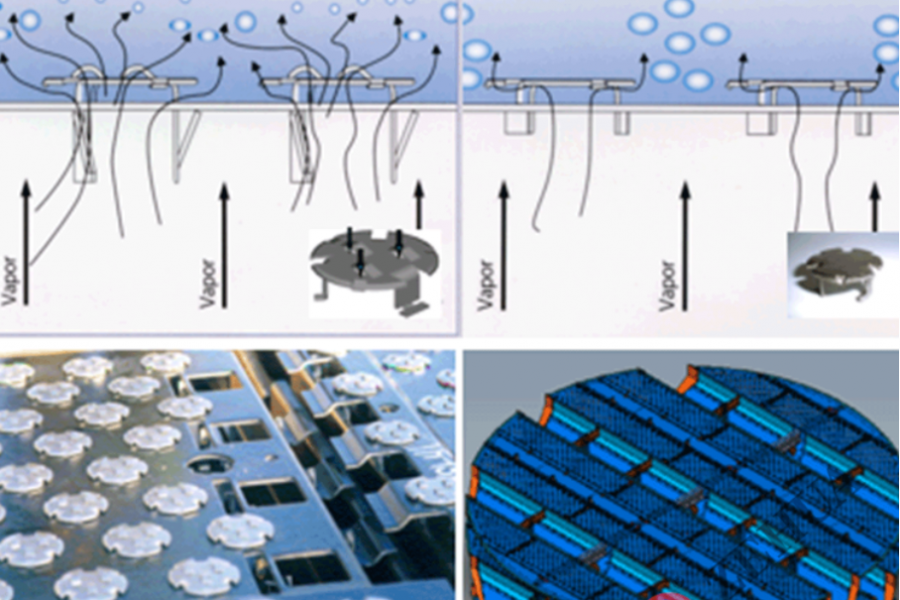

The high-capacity tray is a new type of multi-downcomer tray developed for large column diameter and high liquid loading cases. The tray is based on high performance tray and combines features of multi-pass tray flow. With optimized new downcomer design, it provides higher mass-transfer efficiency and larger liquid capacity in rectification and absorption process. Compared to traditional 4-pass tray, it can increase capacity by at least 25% with comparable tray efficiency

● Improved multi-downcomer tray based on multi-pass tray flow characteristics for reference

● With lateral or longitudinal downcomers, liquid on the tray will form radicalised flow or parallel flow which avoid stagnant pool and increase flow path length

● Parallel liquid flow with same path lengths maintains the same vapor to liquid ratio

● Higher mass transfer efficiency by overcoming the liquid maldistribution that

occurs on a traditional multi-downcomer tray.

● Weir liquid loading can be decreased compared to that of 4-pass and 6-pass trays. This scenario increases tray capacity, especially in high liquid loading.

● Adapts to rectification and absorption process with high mass-transfer efficiency requirement and large liquid capacity cases

Main Features Application Fields

- Valve with top canopies - Atmospheris and vacuum units of petroleum

- Directional valves - FCCU

- Bubble promotor - Light hydrocarbon seperation

- Non-revolving valve - Hydrogenation

- Improved tray deck connection - Coking

- - Reform and aromatics complex

- - Methanol plant

- - Acetic acid

- Polysilicon

Advantages over Conventional trays

- Higher capacity by 40% or more

- Efficiency increase by 10-20%

- Lower pressure drop by more than 10%

- Greater flexibility by 30-50%

- Minimum modification in reconstruction

- Easy to install

TRAY SERIES

- Valve tray

- Floating round valve with top canopies to fine dispersion

- Anti-spin to avoid valve legs abrasion

- High performance in efficiency and capacity

- Wide operation flexibility

- R Valve tray

- Floating rectangular valve with canopies to fine dispersion

- F tray

- More efficiency and higher flexibility than conventional trays

- Adapt to fouling and coking system